Concrete batching plants play a pivotal role in the construction industry, ensuring a steady supply of high-quality concrete for various projects. In this comprehensive guide, we will delve into the top 10 types of concrete batching plant and their usage. Additionally, we will explore the advantages of renting a used batching plant, shedding light on cost-effective solutions for businesses. Whether you're in need of a temporary solution or considering a long-term investment, learning about the used batching plant for Rent and Sale is crucial for informed decision-making. This guide aims to provide clear, straightforward information, making it accessible to individuals at all levels of familiarity with concrete batching technology.

Concrete batching plants play a pivotal role in the construction industry, ensuring a steady supply of high-quality concrete for various projects. In this comprehensive guide, we will delve into the top 10 types of concrete batching plant and their usage. Additionally, we will explore the advantages of renting a used batching plant, shedding light on cost-effective solutions for businesses. Whether you're in need of a temporary solution or considering a long-term investment, learning about the used batching plant for Rent and Sale is crucial for informed decision-making. This guide aims to provide clear, straightforward information, making it accessible to individuals at all levels of familiarity with concrete batching technology.

Batching Plant

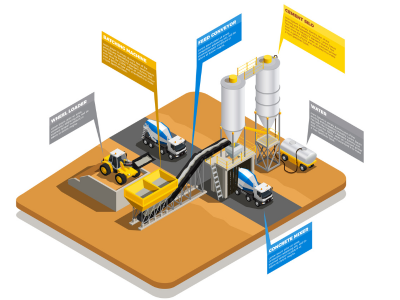

A batching plant, also known as a concrete plant or concrete batching plant, is a facility that combines various ingredients to form concrete. It operates by systematically blending aggregates like sand, gravel, and water with cement and additives in predetermined proportions. This process ensures consistent and high-quality concrete production. Batching plants come in different types, such as stationary, mobile, and compact plants, each designed for specific construction needs. They play a crucial role in large-scale projects like roads, bridges, and buildings. Batching plants enhance efficiency by automating the mixing process, reducing manual labor, and providing precise control over concrete composition, leading to durable and reliable construction materials.

Advantages of Renting a Used Batching Plant

1. Cost-Efficiency: Renting a used batching plant is often more economical than purchasing a new one, as it eliminates the initial high investment.

2. Immediate Availability: Used plants are readily available for rent, allowing for quick deployment on-site, which can be crucial in time-sensitive projects.

3. Tested Performance: A used batching plant has a track record, providing assurance of its operational reliability and performance based on previous usage.

Types of a Batching Plant

Type 1: Stationary Concrete Batching Plant:

A stationary concrete batching plant remains fixed in one location throughout the project duration. It is set up at a chosen site and stays operational until the project is complete.

Usage:

- Large Projects: Stationary plants are ideal for significant construction endeavors like bridges, dams, and skyscrapers where a consistent and high-volume supply of concrete is required.

- Precise Mixing: They offer precise control over the mixing process, ensuring high-quality concrete meeting specific project requirements.

Type 2: Mobile Concrete Batching Plant:

A mobile concrete batching plant is designed for easy transportation between different job sites. It can be quickly set up and disassembled, allowing for flexibility in project locations.

Mobile plants are perfect for projects that require concrete at various locations, such as road construction, small buildings, or infrastructure repairs.

They excel in situations where speedy setup is crucial, enabling prompt response to changing project needs.

Type 3: Compact Concrete Batching Plant:

A compact concrete batching plant is designed to provide high efficiency and production capacity within a limited space. It is characterized by its small footprint and efficient layout. Compact plants are ideal for construction sites with restricted space, enabling efficient concrete production without compromising on quality. They are well-suited for smaller construction projects like residential buildings, small bridges, or urban infrastructure developments.

Type 4: Dry Mix Concrete Batching Plant:

Description: A dry mix concrete batching plant pre-mixes all components except water before being loaded into the mixer truck. This type is known for its precision in concrete composition.

Usage:

- Precise Mix Proportions: Dry mix plants are preferred when exact measurements of ingredients are crucial, ensuring consistent concrete quality.

- Specialized Applications: They are commonly used for projects with specific concrete requirements, such as precast concrete elements or decorative applications.

Type 5: Wet Mix Concrete Batching Plant:

A wet mix concrete batching plant combines all components, including water, within the plant before loading into the mixer truck. It is known for producing consistently high-quality concrete mixes.

Usage:

- High-Quality Concrete Production: Wet mix plants are favored for projects that demand a superior and uniform concrete mix, ensuring structural integrity and durability.

- Large Scale Projects: They are well-suited for significant constructions like highways, airports, and large buildings, where a high volume of concrete is required.

Type 6: Central Mix Concrete Batching Plant:

A central mix concrete batching plant mixes all ingredients centrally in the plant before loading into the mixer truck. It is known for producing exceptionally high-quality concrete due to precise control over the mixing process.

Central mix plants are essential for projects that require the highest level of concrete quality, such as major infrastructure projects or large commercial buildings.

They offer meticulous control over the mixing process, resulting in uniformly mixed and high-strength concrete batches.

Type 7: Transit Mix Concrete Batching Plant:

A transit mix concrete batching plant mixes concrete during transportation in the truck's rotating drum. It is designed for projects that require on-site mixing and immediate delivery. Transit mix plants are essential for projects in areas where a stationary plant is impractical, ensuring fresh concrete is delivered to even the most challenging sites. Ideal for situations where prompt concrete delivery is crucial, such as emergency repairs or urgent construction needs.

Type 8: Continuous Concrete Batching Plant:

A continuous concrete batching plant operates without interruption, providing a steady supply of concrete. It continually mixes concrete as per the requirements.

Usage:

- High Demand Projects: Continuous plants are crucial for projects with a constant need for concrete, ensuring a reliable and uninterrupted supply.

- Large-Scale Infrastructure: They are essential for major infrastructure projects like highways, airports, and dams, where a high volume of concrete is needed consistently.

Type 9: Batch Type Concrete Batching Plant:

A batch type concrete batching plant processes one batch of concrete at a time. It is suitable for projects with specific mix requirements.

Usage:

- Customized Mixes: Batch type plants are used when precise control over concrete composition is essential, ensuring the exact mix required for specialized applications.

- Small to Medium Projects: They are well-suited for projects where the demand for concrete is moderate, such as residential buildings, small-scale infrastructure, or individual construction needs.

Type 10: Automatic Concrete Batching Plant:

An automatic concrete batching plant operates with full automation, controlled by computer systems. It ensures precise mixing, batching, and discharge of concrete.

Automatic plants are suitable for projects where a high level of automation is desired, streamlining the concrete production process and reducing manual intervention.

They ensure consistent and precise mixing, resulting in high-quality concrete batches that meet specific project requirements.

Final Thoughts

Understanding types of a concrete batching plant is crucial for optimizing construction processes and selecting the most suitable plant for specific project requirements. Whether it's the stationary plants for large-scale endeavors, mobile plants for flexibility, or compact plants for space-saving solutions, each type serves a specific purpose. Moreover, recognizing the advantages of renting a used batching plant, such as cost-efficiency, immediate availability, and reduced maintenance costs, can be a game-changer for businesses. This consideration is particularly significant in the context of the availability of used batching plants for rent and sale, providing accessible options for both temporary and long-term projects. Making informed choices about the types and rental options ensures that concrete production is optimized, leading to durable and reliable construction materials for a wide array of projects.

Equipmentrentalsindia.com is a website that provides a platform for renting, reselling, and buying different types of a concrete batching plant. Concrete batching plants are devices that mix various ingredients to form concrete, which is essential for many construction projects. Equipmentrentalsindia.com helps the people who need used batching plants for rent and sale by connecting them with the owners and companies who have them. The website also offers second hand concrete batching plants for sale at reasonable prices. By using equipmentrentalsindia.com, people can save time, money, and resources while getting access to quality concrete batching plants across India.

FAQ Questions

1. What are the factors to consider when choosing a used batching plant?

Condition, brand reputation, production capacity, and maintenance history are factors to consider when choosing a used batching plant.

2. What are the main parts of the batching plant?

The main parts of a batching plant include aggregate bins, conveyors, cement silos, mixing unit, and a control panel.

3. Where can I get a used batching plant?

Used batching plants can be obtained from specialized dealers, online marketplaces, or through rental companies that offer both used and new equipment.

4. What is the use of batching plants in construction?

Batching plants in construction are used to mix various ingredients like aggregates, cement, water, and additives to produce concrete, which is essential for building structures and infrastructure.

5. What is the capacity of a concrete batching plant?

The capacity of a concrete batching plant can vary widely, ranging from small plants with capacities of around 20 cubic meters per hour to large plants that can produce hundreds of cubic meters per hour.